About Our Services

Campos Fabrication has worked hard to exceed customer expectations since its founding. This means you get consistent communication from project managers and engineers and incredible quality from expert fabricators.

Campos Fabrication has worked hard to exceed customer expectations since its founding. This means you get consistent communication from project managers and engineers and incredible quality from expert fabricators.

Campos Fabrication is more than just a Fabricator.

Campos Fabrication provides the quality engineering and design support our clients have come to expect from our sister company Campos EPC, with the additional support of a full operational fabrication shop. Our internal engineering and design teams can help take projects from concept through commissioning, provide a single point of contact, and leverage professional experience as needed from our 700+ energy-focused CEPC colleagues, providing a true one-stop shop for all of your needs.

Campos Fabrication is capable of managing and cutting many various times of materials through our shop. Whether it be through the use of our large capacity bandsaw for flat stock and structural steel, or pipe through the use of our cutting-edge Revolving CNC cutting machine from Lone Star Cutting Solutions.

Band Saw

Campos fabrication utilizes an Amada Marvel S330 3 HP Horizontal Automatic Bandsaw to handle the processing and cutting of our steel stock.

This machine is capable of handling cuts up to 12″ Beams, 13″ Rounds, 13″ Squares, 12″ x 18″ Rectangles, and 11” thick Material. Additionally, we can accommodate -45 to +60 degree miter cuts.

Plasma Table

Campos Fabrication utilizes a Lonestar Trooper Plasa Table. Our table is capable of cutting 1-1/2″ thick carbon steels and 1/2″ thick stainless steels with a positioning accuracy of (+/-) .007″ and a max traverse speed of 1000 ipm.

Lone Star CNC Revolver

Capacity: Our machine is designed to handle pipes up to 24 inches in diameter and 1 inch thick, providing versatility for a wide range of projects.

Speed: With a cutting speed of up to 800 inches per minute (ipm), we ensure efficient production without compromising precision.

Accuracy: Experience superior accuracy with a margin of error as low as +/- 0.007 inches, ensuring your cuts meet the strictest standards.

Technology: Powered by the Emax whisper air compressor featuring silent air technology, our machine utilizes the Hypertherm plasma cutting torch Power Max 105, guaranteeing optimal performance and reliability.

CNC Cutting: Seamlessly import CAD files or spool lengths for precise cutting tailored to your specifications.

Efficiency: Maximize productivity with our machine’s ability to measure, cut, and bevel multiple sections from a single spool of pipe, reducing both time and material waste.

Versatility: From fish mouths to O-lets, our machine is capable of handling various cutting tasks with ease.

Beveling: Achieve precise bevel angles of up to 45 degrees, ensuring your components fit seamlessly into your projects.

Simplicity: Eliminate the need for grinding, drilling, and additional cutting processes, streamlining your workflow for enhanced efficiency.

Expertise: Rest assured, our team of qualified personnel is fully certified to operate the machine, providing you with peace of mind and professional service.

Campos Fabrication has implemented the use of the PipeWorx 400 system from Miller Welding at our facilities. Each of our facilities Through this technology, we are able to streamline our welding setup, resulting in a straightforward setup that requires minimal steps to initiate, thereby reducing training time and mitigating errors. The implementation of this technology allows for a comfortable welding environment for our skilled technicians.

With the PipeWorx ‘Quick-Select’ technology, process changeovers are executed swiftly and accurately. This innovative feature automatically discerns the welding process, and corrects polarity, cable outputs, and welding parameters, eliminating the need for manual adjustments and minimizing setup time.

Beyond simplifying setup and changeovers, our solution offers additional advantages, including a notable reduction in weld time, facilitated by integrated inductance control, arc length, and trim adjustment functionalities. Furthermore, our custom programmable weld software empowers users with granular control over welding parameters, enhancing process customization and optimization.

Welcome to Campos Fabrication, your trusted partner for engineering, automation, electrical, instrumentation, control design, and production services. Our seasoned team of engineers, designers, and technicians stand ready to address any challenge that arises throughout your project journey. Backed by a solid reputation for excellence, innovation, and reliability, and access to industry-leading product lines, we deliver bespoke solutions tailored to the specific requirements of our clients. Highlighted below are some of the capabilities we offer:

Services:

Solutions:

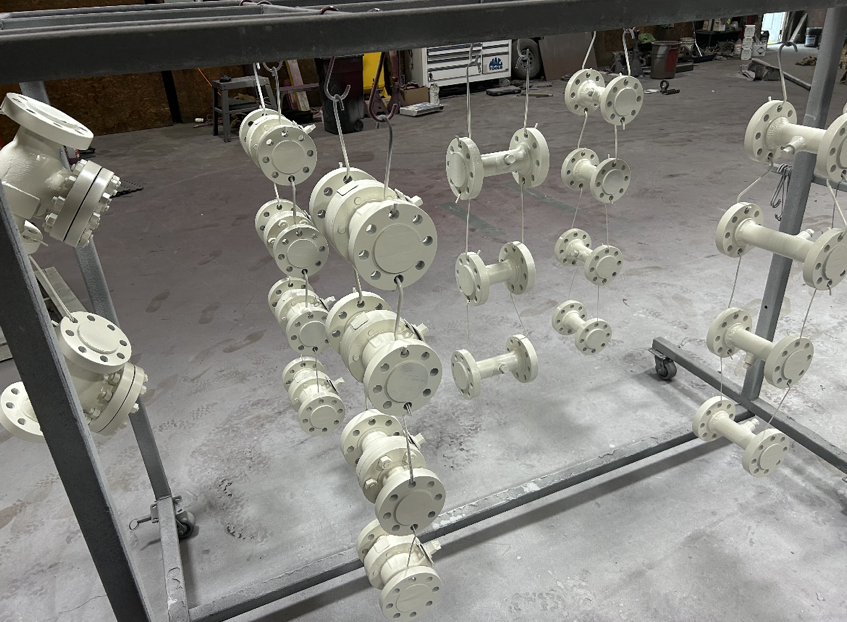

Campos Fabrication offers a wide selection of painting services through the use of our state-of-the-art Paint Booth, crafted in collaboration with Paint Projects, Inc. and Benjamin Moore.

Our Paint Booth boasts cutting-edge technology designed to meet the highest standards in the industry. With dimensions of 12’x12’x25’ and equipped with a 34” exhaust fan, it ensures optimal ventilation and air quality, which refreshes the air 7 times per minute, guaranteeing a safe and effective workspace.

We understand that every project is unique, which is why we offer a range of Benjamin Moore paint products, with alternatives available to suit individual preferences. Backed by our expertise, experience, and the latest equipment and supplies, we have the capability to tackle any job with precision and finesse.

Should you need a more unique coating type beyond our scope, our team of subcontracted partners can provide the skills and expertise required to provide your specialty coating, ensuring that no project is beyond our scope.

Quality in Safety

We prioritize safety above all else, ensuring that it remains a cornerstone of our operations. Through daily safety huddles, our rigorous safety planning, and a focus on safety in everything we do, we foster a culture of vigilance and awareness. Our commitment extends to robust safety planning, ensuring that protocols are in place to mitigate risks effectively. Moreover, all our staff are certified with either OSHA 10 or OSHA 30-hour certification, demonstrating our unwavering dedication to maintaining a safe working environment.

Quality in Design

We uphold rigorous standards of quality in every aspect of our design process. With dedicated project management, we ensure that each project is meticulously overseen from inception to completion. Our dedicated QAQC staff rigorously reviews all deliverables, guaranteeing the highest standards of excellence. Furthermore, project stakeholder reviews and hold points are integrated into our process to ensure alignment with client expectations. We also conduct internal Constructability Reviews to identify and address potential issues proactively. Additionally, we facilitate up-front coordination between our engineering and production teams through dedicated pre-fabrication meetings, fostering seamless collaboration and ensuring that projects are executed efficiently and to the highest quality standards.

Quality in Fabrication

Quality is ingrained in every step of our fabrication process, ensuring that our products meet the highest standards of excellence. We employ detailed internal quality processes that guide every aspect of fabrication. From procurement to material receipt and inspection, and through to field material receipt and inspection, we adhere to formal written processes to guarantee precision and reliability. Our commitment to quality extends to pressure testing and coating thickness, where meticulous attention is paid to ensure integrity and durability. We uphold rigorous standards for welding, with approved Welder WPS, PQR, and continuity programs implemented for both carbon and stainless pipe fabrication. Furthermore, weld inspections are conducted by a contracted third-party inspection company to ensure that our welding meets the highest quality standards. We seamlessly integrate customer inspection requirements into our processes, ensuring alignment with client expectations.

Campos Fabrication, as a member of the Campos family of companies, is structured for and experienced in offering full turnkey/EPC solutions to our clients. With a full suite of services across our companies, we can leverage our in-house team of professionals or call on our large bench of engineers, designers, procurement specialists, and project managers, as well as a vast network of subcontractors across our companies.

Our team of experts has experience facilitating and managing every aspect of utility design and construction, from skids to complete site buildout.

SERVICES

Assisting customers in achieving their specific project goals through collaborative quality engineering and state-of-the-art fabrication.

We understand that all projects are unique. Upon initiation of a project a CFAB project manager is assigned as the primary point of contact to kick off the project. At Campos Fabrication, our interdisciplinary team collaborates promptly to strategize the most efficient and economical approach to project completion, prioritizing client satisfaction. Rigorous price analysis is conducted to secure top-tier materials at optimal market rates through our partner networks.

Utilizing designs developed by our skilled engineers, our best-in-class production teams commence precise fabrication, adhering meticulously to project specifications. Subsequent to fabrication, our in-house quality assessment ensues, meticulously validating conformance to design specifications and suitability for intended application.

Upon successful completion of inspection, our coating procedure commences within our controlled environment paint booth, ensuring an impeccably high-quality finish.

Project Planning & Design

Assembly & Welding

Quality Assurance & Inspection

Coating

Quality Control

Commissioning