Catalog

Select a topic

Read about your topic

RNG Projects

Hydrogen Projects

Metering and Regulation

Odorization

ASME Projects

Automation

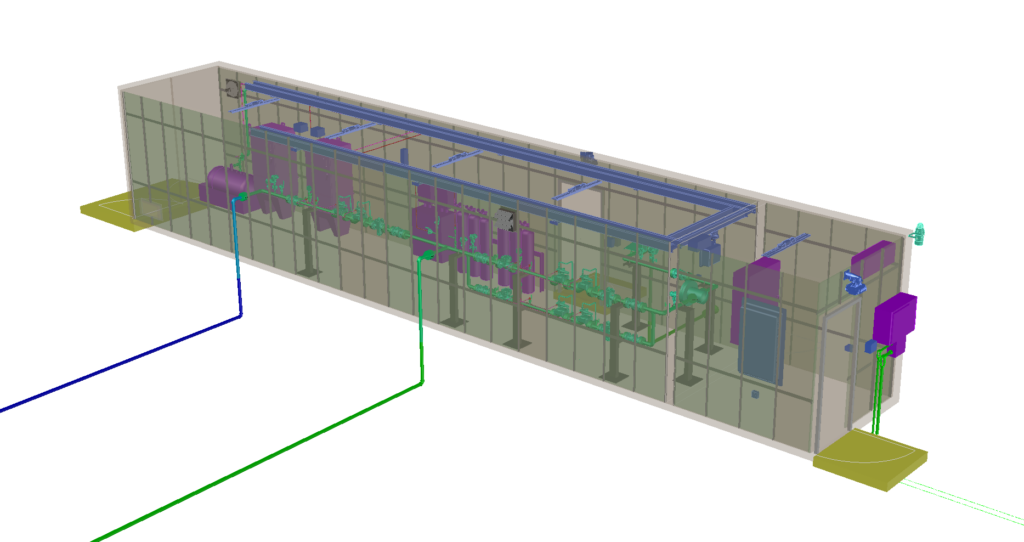

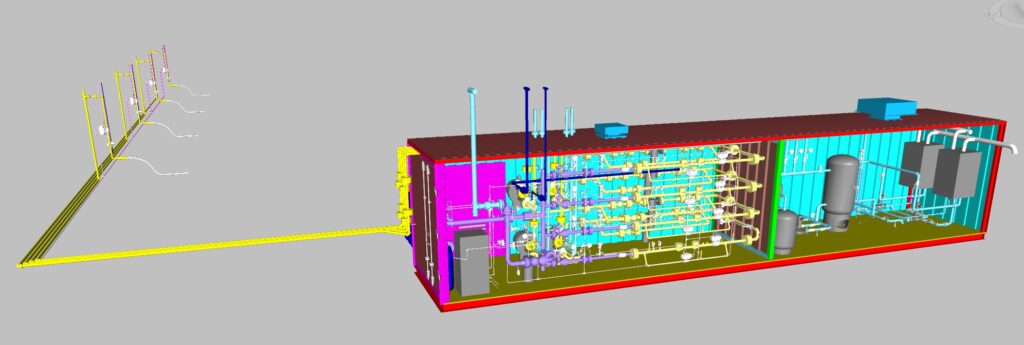

Housed in a 53’ High Cube Connex Box, Campos Fabrication provides a Renewable Natural Gas Interconnect Skid fully customized to our Client’s specifications and needs. This design utilizes a single-worker monitor regulator concept to provide overpressure protection along with custody transfer metering. This design features:

Process Conditions

- ANSI 150 Pressure Class

- 275 psig MAOP

- 2in Inlet and 4in Outlet

- Flow Rate: 42 mcfh @100 psig

- Pressure Cut from 275 psig to 60 psig

- 250-gallon odorant tank with Emerson Tartarini™ Type DO200 Odorant Injection System

EIC and Controls

- C1D2 Group D Process Room (HVAC upon request)

- DAC Room (Data, Acquisition, and Controls) w/full HVAC

- Air-Tight Vapor Wall to separate C1D2 Group D Process Room from Unclassified DAC Room

Analytical Equipment

- Hobre and Baker Hughes gas analyzers for H2S, O2, CO2 and Moisture

- Rosemount C6+ Chromatograph

- Rosemount Pressure and Temperature Sensors located at the inlet, and both pressure cuts

Safety Systems

- Emerson Gas and Flame Detection

- Anderson Greenwood 4”x3” Pressure Relief Valves to provide redundant overpressure protection.

With a Campos Fabrication project, we can always provide:

- 100% NDE with test reports with radiographic films available upon request

- 1.5x MAOP Hydrostatic Pressure Testing with Charts Provided

- 100% Material Traceability

- Full Digital Job Book

- Will meet a client’s specifications for valves and coating

- Country of origin material restrictions can be met upon request

- Site Installation/Commissioning Upon Request

A variation of our default RNG Interconnect Skid Design for applications requiring a significant pressure change from developer to pipeline network. This skid utilizes a similar concept to our single run skid and is housed in the same 53’ Conex Box, but utilizes a redundant regulator run to achieve the process control. This design features:

Process Conditions

- ANSI 600 Pressure Class

- 1000 psig MAOP

- 2” inlet and 4” outlet

- Flow Rate: 40 mcfh @ 600psig

- 2 Independent Pressure Cuts utilizing a worker monitor setup

- 1st run: 1000 psig to 450 psig

- 2nd run: 450 psig to 60 psig

- 60-gallon Odorant Tank and Zero Emission Redundant System

EIC and Controls

- C1D2 Group D Process Room (HVAC upon request)

- DAC Room (Data, Acquisition, and Controls) w/full HVAC

- Air-Tight Vapor Wall to separate C1D2 Group D Process Room from Unclassified DAC Room

Analytical Equipment

- Hobre and Baker Hughes gas analyzers for H2S, O2, CO2 and Moisture

- Rosemount C6+ Chromatograph

- Rosemount Pressure and Temperature Sensors located at the inlet, and both pressure cuts

Safety Systems

- Emerson Gas and Flame Detection

- Anderson Greenwood 3”x2” Pressure Relief Valves to provide redundant overpressure protection.

With a Campos Fabrication project, we can always provide:

- 100% NDE with test reports with radiographic films available upon request

- 1.5x MAOP Hydrostatic Pressure Testing with Charts Provided

- 100% Material Traceability

- Full Digital Job Book

- Will meet a client’s specifications for valves and coating

- Country of origin material restrictions can be met upon request

- Site Installation/Commissioning Upon Request

Upon Completion, the product will ship in 3 parts: The main skid and the 2 relief valves and stacks.

/>

Campos Fabrication’s Truck decompression skid can handle up to 4 independent truck runs within a 53’ High Cube Conex Box that each allows for a pressure reduction from 3783psig to 450 psig before being directly injected into a customer’s pipeline. Each run is designed and fabricated to feature:

Process Conditions

- ANSI 2500/600/300 Pressure Classes

- 3783 psig MAOP

- Flow Rate: 160 mcfh @ 450 psig

- Two Independent Pressure Cuts utilizing worker monitor setup

- 1st Cut: 3783psig to 700 psig

- 2nd Cut: 700 psig to 450 psig

- Outlet Pressure can be cut to the client’s specifications.

- -100°F Degree Inlet Temperature

- 50-gallon odorant tank with Emerson Tartarini™ Type DO200 Odorant Injection System

EIC and Controls

- C1D2 Group D Process Room (HVAC upon request)

- Air-Tight Vapor Wall to separate C1D2 Group D Process Room from Unclassified Boiler Room

- Unclassified Boiler Room with high efficiency Spiral Wound Heat Exchanger

- Automatic Startup/Shutdown (Based on Truck Station Valve Open/Closed Status) with 5 min Pre-heat

Analytical Equipment

- Hobre and Baker Hughes gas analyzers for H2S, O2, CO2 and Moisture

- Rosemount C6+ Chromatograph

- Rosemount Pressure and Temperature Sensors located at the inlet, and both pressure cuts

- Pressure/Temperature monitoring throughout Skid

Safety System

- Automatic Emergency Shutdown

- Emerson Gas and Flame Detection

- Anderson Greenwood 4”x3” Pressure Relief Valves

Upon Completion, skid will ship with loose relief valves for field bolt-up and commissioning.

With a Campos Fabrication project, we can always provide:

- 100% NDE with test reports with radiographic films available upon request

- 1.5x MAOP Hydrostatic Pressure Testing with Charts Provided

- 100% Material Traceability

- Full Digital Job Book

- Will meet a client’s specifications for valves and coating

- Country of origin material restrictions can be met upon request

- Site Installation/Commissioning Upon Request

Campos Fabrication and NECI collaborated on a first-of-its-kind hydrogen-blending cabinet. This cabinet allows for Hydrogen Gas to be blended with Natural Gas in a user-controlled range of 2-20%, allowing for a cleaner and cost-effective energy supply. Housed in a sleek and spatial-conscious cabinet, our design features:

Process Conditions

- ANSI 150 Pressure Class

- 250 psig MAOP (H2 is required to be 5psig higher than Natural Gas inlet for cabinet to operate)

- Flowrate: 1 mcfh @ 60psig

- Stainless Steel Tubing

- Static Mixing Element and H2 Process Analyzer to ensure proper blending

EIC and Controls

- C1D2 Grade B Rated Equipment

- Rosemount 3051T Pressure indicating transmitter (PIT) on Outlet

Safety Systems

- Anderson Greenwood Relief Valve

Campos Fabrication developed a large-scale Hydrogen metering skid. hydrogen-blending cabinet. This skid fabricated 100% out of stainless steel allows our customer to efficiently and safely measure high quantities of hydrogen and adapt to a launcher receiver barrel to allow for in-line inspection of the piping.:

Process Conditions

- ANSI 600 Pressure Class

- 915 psig MAOP

- Flow Rate: 60.1 mmscfd @ 770 psig

- Carbon Steel Design

Analytical Equipment

- Coriolis Meter for Custody Transfer

- Rosemount Pressure and Temperature Sensors

Safety Systems

- Automatic Emergency Shutdown

- Anderson Greenwood Relief Valves

Frame Design

- AWS D1.1 Welded Skid Frame

- Bar grating flooring

Campos Fabrication is equipped to design a Gate Station Skid to a client’s desired specifications and needs. Our standard design features:

Process Conditions

- ANSI 300 Pressure Class

- 740 psig MAOP

- 8” Inlet and 12” Outlet

- 6” Regulators, Worker Monitor configuration with (2) runs

- Strainers on inlet piping

- 6” Bypass run for use during repair or maintenance

Frame Design

- AWS D1.1 Welded Skid Frame

- 84” x 220” frame footprint

- Bar grating or diamond plate flooring is available upon request

Safety Systems

- Anderson Greenwood 8”x6” Pressure Relief Valves

Additionally, the skid design can be adjusted for the inclusion of client-preferred regulators and scaled for ANSI Classes 150-600 and pipe sizes 2”-12” allowing for scalable customization and repeatability. CFAB can augment this design to meet any client preference when it comes to layout, equipment, valve, and paint specifications.

With a Campos Fabrication project, we can always provide:

- 100% NDE with test reports with radiographic films available upon request

- 1.5x MAOP Hydrostatic Pressure Testing with Charts Provided

- 100% Material Traceability

- Full Digital Job Book

- Will meet a client’s specifications for valves and coating

- Country of origin material restrictions can be met upon request

- Site Installation/Commissioning Upon Request

Upon completion, the product will ship in 3 parts: The main skid and the 2 headers. The 3 risers on both headers will ship long for field installation.

Campos Fabrication is well-equipped to support your programmatic efforts, even when it comes to smaller assemblies. CFAB Recently provided a suite of meter sets to replenish stock for a utility that was looking for a more efficient way than to field install them. CFAB developed a template and was able to produce the meters faster and more effective than the field built to a client’s design and specifications. The features of these meter sets included:

- 3M, 5M, and 7M Dresser Rotary Meter Size Ratings

- 2” Piping

- Each unit came pre-packaged with a coded field assembly kid provided.

- 100% Material Traceability

- Full Digital and Physical Job Book

- Will meet a client’s specifications for valves and coating

- Country of origin material restrictions can be met upon request

- Full Material Traceability and documentation

- Individual Digital Job Book for each set

Campos Fabrication is equipped to design and produce a Regulating and Metering assembly to a client’s desired specifications and needs. The features of this assembly include:

Process Conditions

- ASME 150 Pressure Class

- 285 psig MAOP

- 4” Inlet and 4” Outlet

- 2” Regulators, Worker Monitor configuration with bypass

- 4” Meter and Y strainer on inlet with 4” bypass

- 4” Bypass run for use during repair or maintenance

- Piping contained on a 6’x8’ concrete pad

Additionally, the assembly design can be adjusted for the inclusion of client-preferred regulators and scaled for ASME Classes 150-600 and pipe sizes 2”-12” allowing for scalable customization and repeatability. CFAB can augment this design to meet any client preference when it comes to layout, equipment, valve, and paint specifications.

With a Campos Fabrication project, we can always provide:

- 100% NDE with test reports with radiographic films available upon request

- 1.5x MAOP Hydrostatic Pressure Testing with Charts Provided

- 100% Material Traceability

- Full Digital Job Book

- Will meet a client’s specifications for valves and coating

- Country of origin material restrictions can be met upon request

- Site Installation/Commissioning Upon Request

Campos Fabrication is working with the Emerson Impact partner network to provide and integrated odorant solution. The Emerson Tartarini™ Type DO200 Odorant Injection System, the newest iteration of Dosaodor Odorizer, is available for use in Campos Fabrication Skids. Using differential pressure that may already exist in your application, such as the upstream and downstream of a regulator, the DO200 can achieve a more uniform distribution of odorant with smaller injections done at a higher frequency. This pumpless system has very few moving parts, which results in minimized maintenance costs.

Other benefits of the DO200 turnkey skid include:

- High turndown ratio

- Zero Emissions and Reduced Environmental Impact

- Automatic calibration of the system during active use

- Hazardous environment rated

- User-friendly configuration software

- Several Back-Up and Redundancy Options

- Easy Integration with FlowBoss and ROC RTUs

- Rosemount 5300 Guided Wave Radar Level Transmitter

- Anderson Greenwood ASME Relief Valve

- Campos Fabrication ASME U Vessel with custom sizing and pressure rating available

The DO200 is also certified as Explosion Proof Class 1 Div 1 and 2, has a maximum Supply and Injection Working Pressure of 1450psi/100 bar and a temperature range of 14-140°F (-10 – 60°C), allowing for its use in the most challenging of environments. Higher pressures are available upon request. Campos Fabrication, in partnership with NECI, can also provide a turnkey solution, with the control panel, odorant tank, and injection system, at a competitive price and lead time. In the past, Campos Fabrication has successfully implemented this turn-key integration, providing an OEM solution on RNG interconnect skids for multiple clients across the country, and is proud to now provide a drop in solution for existing regulator stations as well.

Campos Fabrication is proud to offer its services for the design, procurement, and fabrication of Pressure Vessels up to 36” in diameter. We pride ourselves on being an ASME Code Shop and compliant with ASME standards for all tank components. Our odorant tank design features:

- Process Conditions

- ANSI 600 Pressure Class

- 1480 psi MAWP @ 100°F

- 1.219” wall thickness

- 76 Gallon Capacity

- Optimized for use with DO200 Odorant Injection System

- NPT Nozzles

- Galvanized Containment Panel rated for 120% Capacity

- ASME U-Stamp Certification

With any Campos Fabrication Tank, you can Expect:

- 100% NDE with test reports with radiographic films available upon request

- 1.5x MAOP Hydrostatic Pressure Testing with Charts Provided

- 100% Material Traceability

- Full Digital Job Book

- Will meet a client’s specifications for valves and coating

- Country of origin material restrictions can be met upon request

- Site Installation/Commissioning Upon Request

Campos Fabrication is proud to offer its services for the design, procurement, and fabrication of Pressure Vessels up to 36” in diameter. We pride ourselves on being an ASME Code Shop and compliant with ASME standards for all tank components. Our WEG expansion tank design features:

- Process Conditions

- ANSI 150 Pressure Class

- 285 psi MAWP @ 100°F

- 0.322 wall thickness

- 48 Gallon Capacity

- NPT Nozzles

- ASME U-Stamp Certification

With any Campos Fabrication Tank, you can Expect:

- 100% NDE with test reports with radiographic films available upon request

- 1.5x MAOP Hydrostatic Pressure Testing with Charts Provided

- 100% Material Traceability

- Full Digital Job Book

- Will meet a client’s specifications for valves and coating

- Country of origin material restrictions can be met upon request

- Site Installation/Commissioning Upon Request

Campos Fabrication is proud to offer its services for the design, procurement, and fabrication of Pressure Vessels up to 36” in diameter. We pride ourselves on being an ASME Code Shop and compliant with ASME standards for all vessel components. Our filter/separator design features:

- Process Conditions

- ANSI 600 Pressure Class

- 1480 psi MAWP @ 100°F

- ANSI 600 RF Flanged Connections

- o 0.500” wall thickness

- Compatible with cartridges used in existing non-ASME units

- NPT Nozzles

- ASME U-Stamp Certification

With any Campos Fabrication Tank, you can Expect:

- 100% NDE with test reports with radiographic films available upon request

- 1.5x MAOP Hydrostatic Pressure Testing with Charts Provided

- 100% Material Traceability

- Full Digital Job Book

- Will meet a client’s specifications for valves and coating

- Country of origin material restrictions can be met upon request

- Site Installation/Commissioning Upon Request

Campos Fabrication is equipped to design and produce customized UL508A certified control panels to the specifications required by our clients. The features of this assembly include:

Process Conditions

- UL508A Certified Panels

- SCADA Integrations

- Custom Enclosures

- Remote Breaker Control Panels

- Industrial Control Panels

- Lighting and Power Panels

- Turnkey Panel Solutions

Campos Fabrication can build these control panels fully integrated to control and monitor all instruments and equipment required in a system. Including but not limited to Gas Chromatographs, Gas Samplers, Pressure/Temperature Transmitters, Flame/Gas Detectors, Odorant Systems, and ESD panels.

With a Campos Fabrication control panel, we can always provide:

- Cable Management Systems

- Panel Servicing

- Factory and Site Acceptance Testing

- Full Digital Job Book

- Site Installation/Commissioning upon request